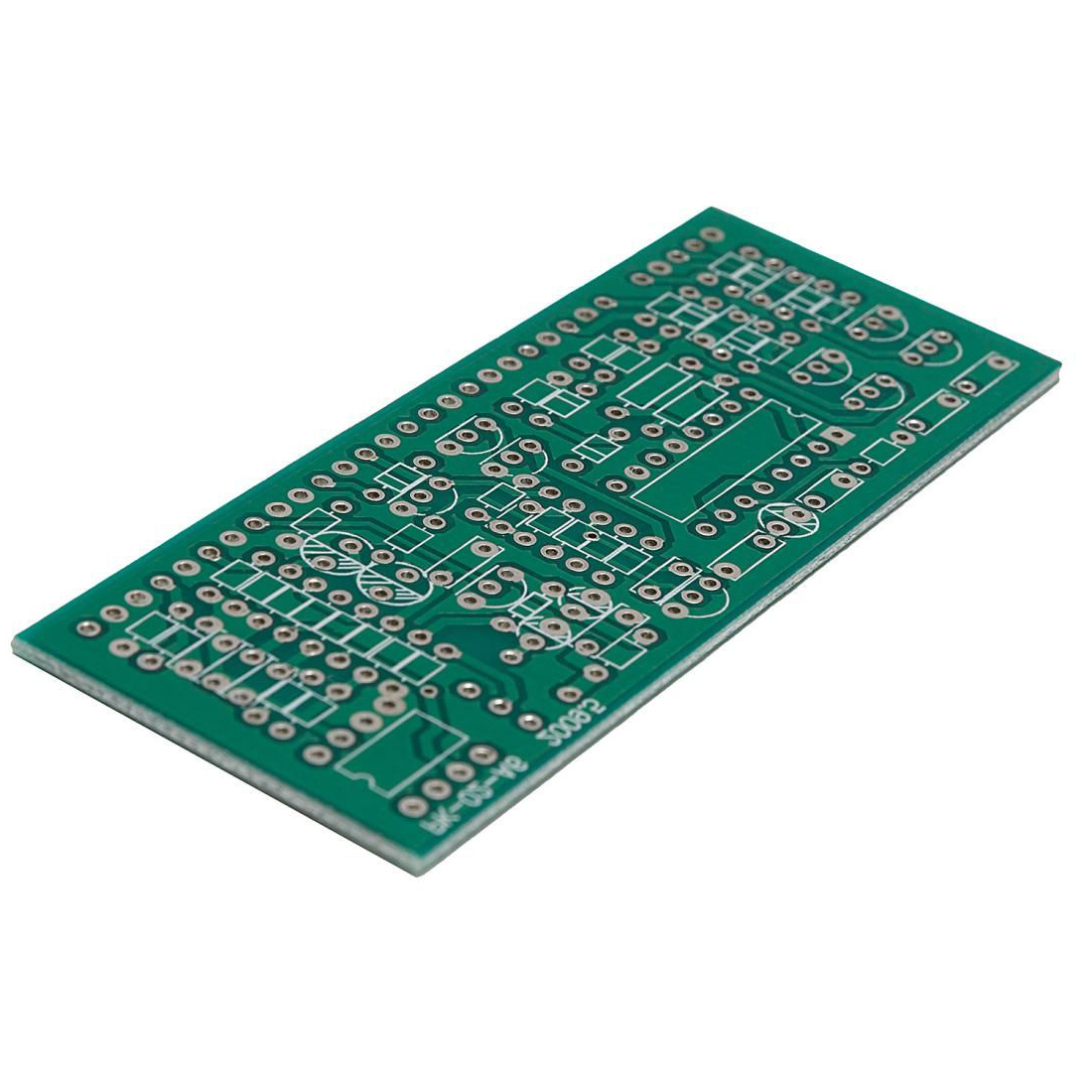

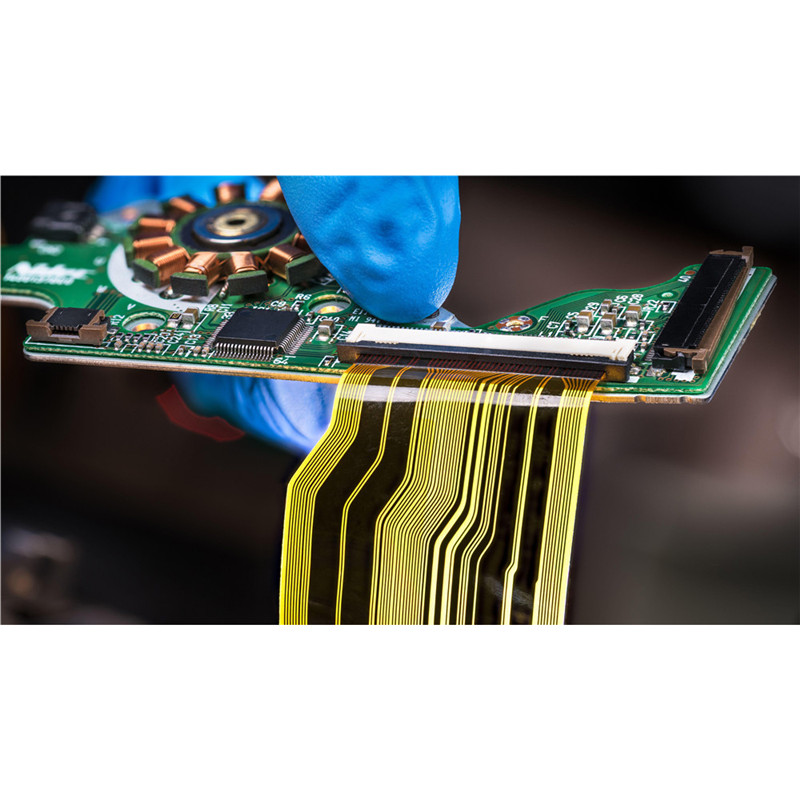

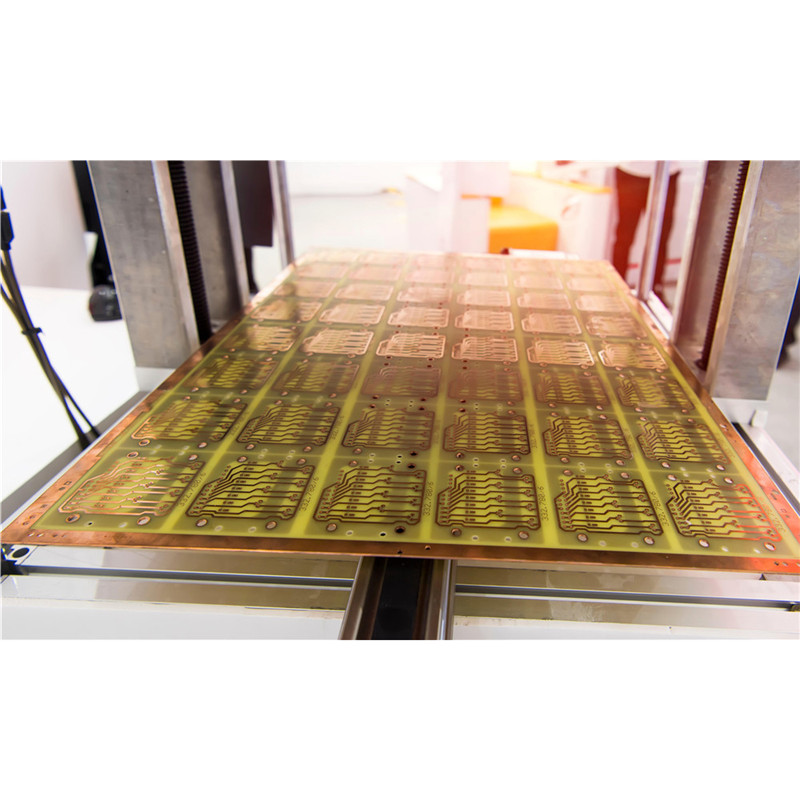

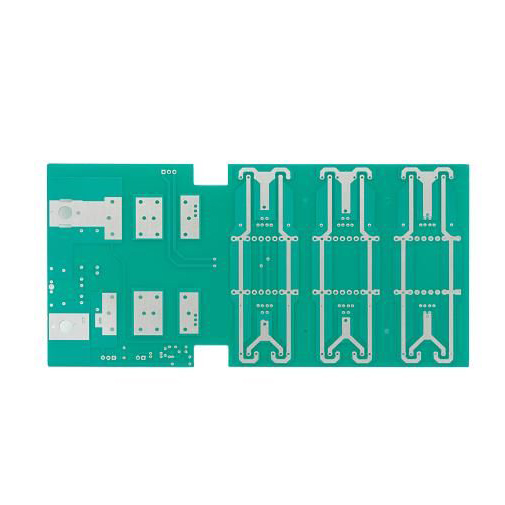

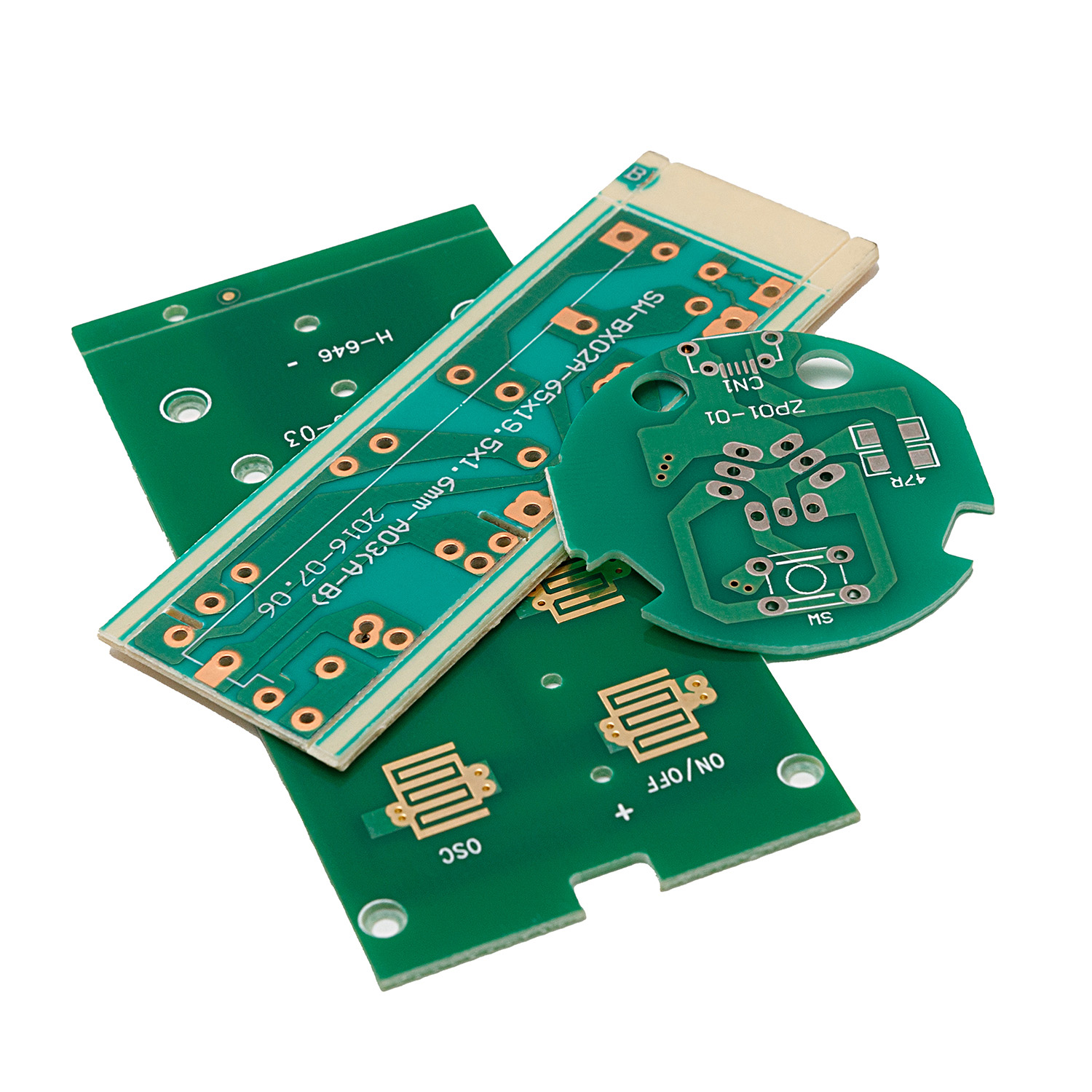

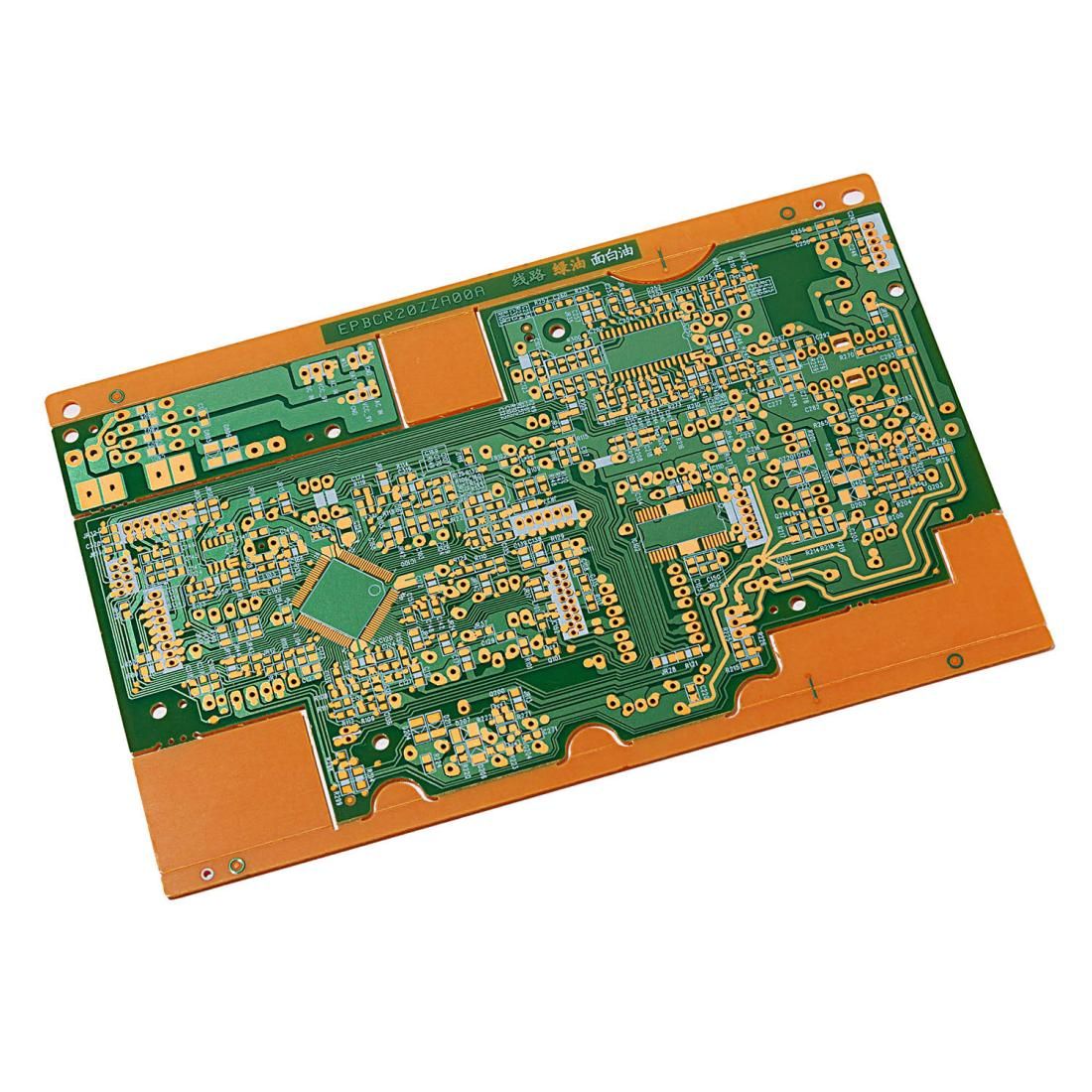

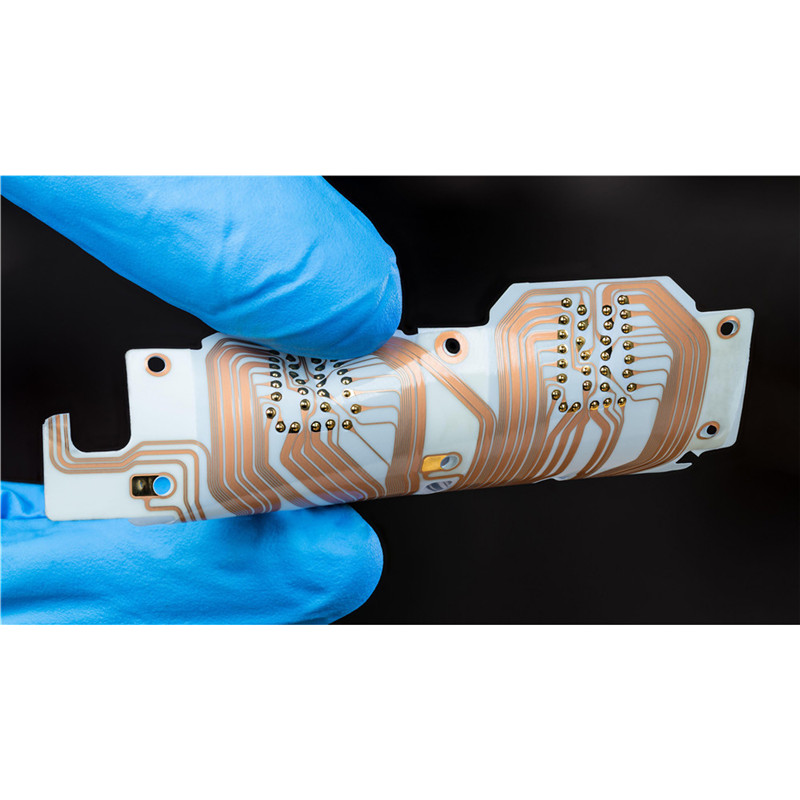

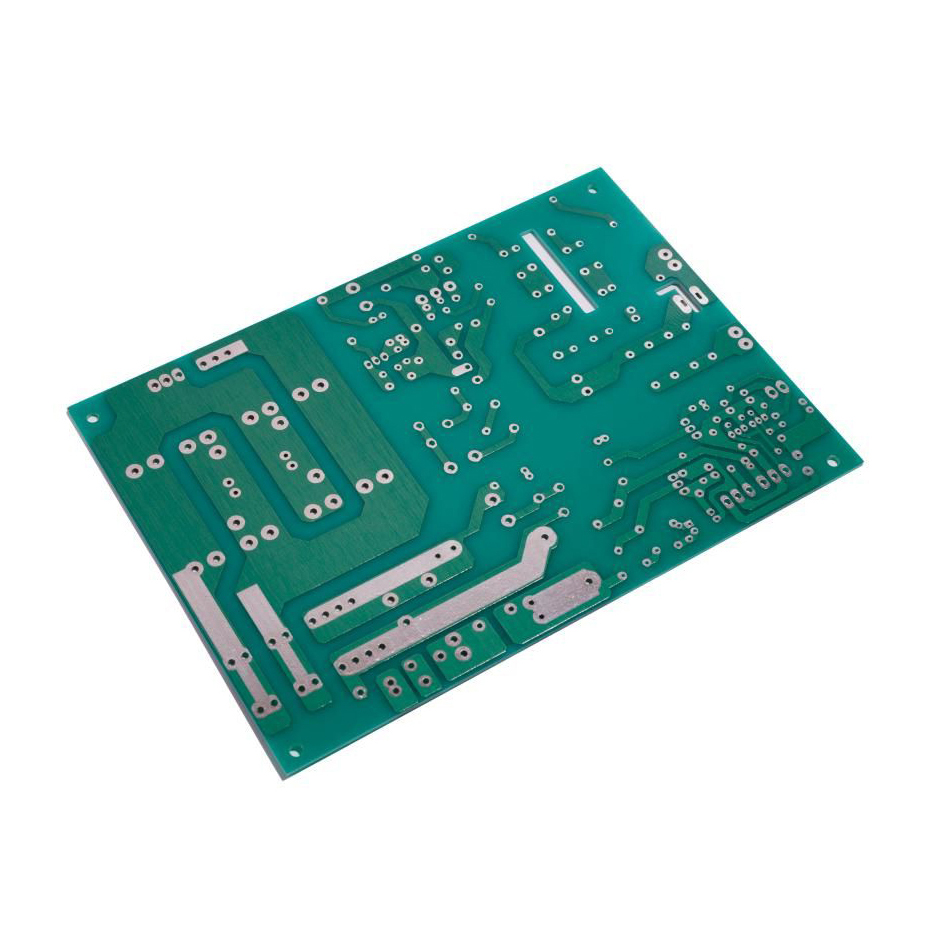

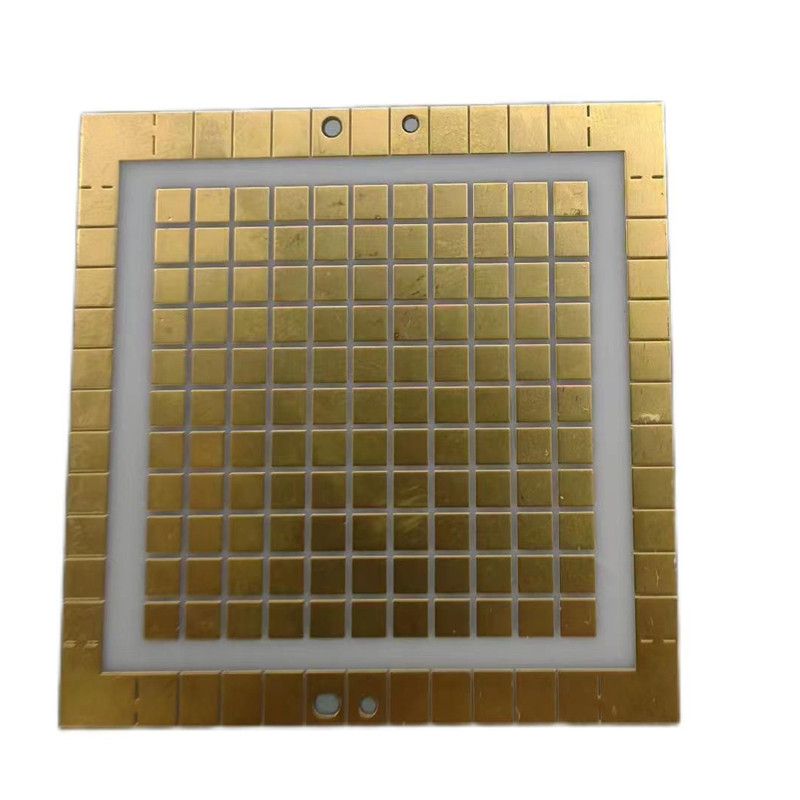

Rigid Flex Printed Circuit Boards

product application

Common applications of rigid flexible combination PCB and semi flexible PCB design

product parameters

|

Feature |

AREX´s technical specification |

|

Number of layers |

1 – 12 layers, with 1 – 2 conductive layers in bending area. |

|

Technology highlights |

The process uses controlled depth routing of the FR-4 to achieve a flexible / bending section within a traditionally rigid FR-4. Only suitable for static operations – bends typically just for installation. A lower cost solution for some very specific “flex-to-fit”applications. |

|

Bending performance |

50 x bend cycles of 0° – 90° – 0° |

|

Bend features |

5mm radius / max bending angle 90° |

|

Materials |

Specialized FR-4 for static flex applications |

|

Copper weights (finished) |

35μm |

|

Minimum track and gap |

0.075mm / 0.075mm |

|

PCB thickness |

1.00mm – 2.00mm |

|

PCB thickness in flex section |

0.25mm ± 0.05mm |

|

Maxmimum dimensions |

538mm x 610mm |

|

Surface finishes available |

HASL (SnPb), LF HASL (SnNiCu), OSP, ENIG, Immersion tin, Immersion silver, Electrolytic gold, Gold fingers |

|

Minimum mechanical drill |

0.20mm |

|

Minimum laser drill |

0.10mm standard, 0.075mm advanced |