01

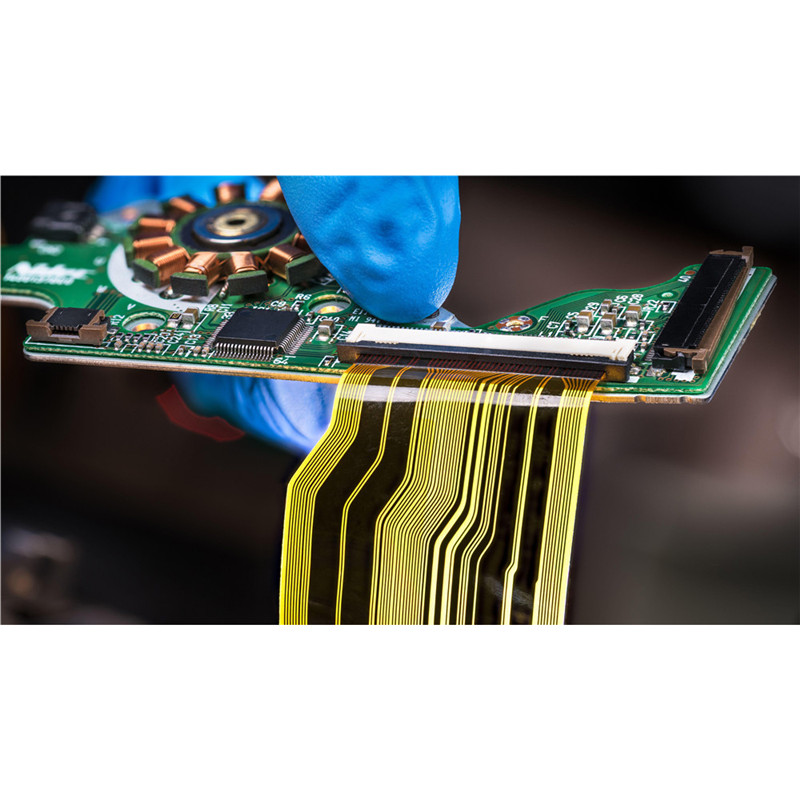

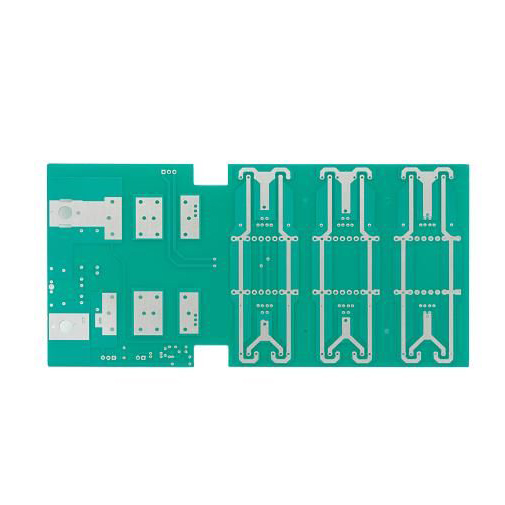

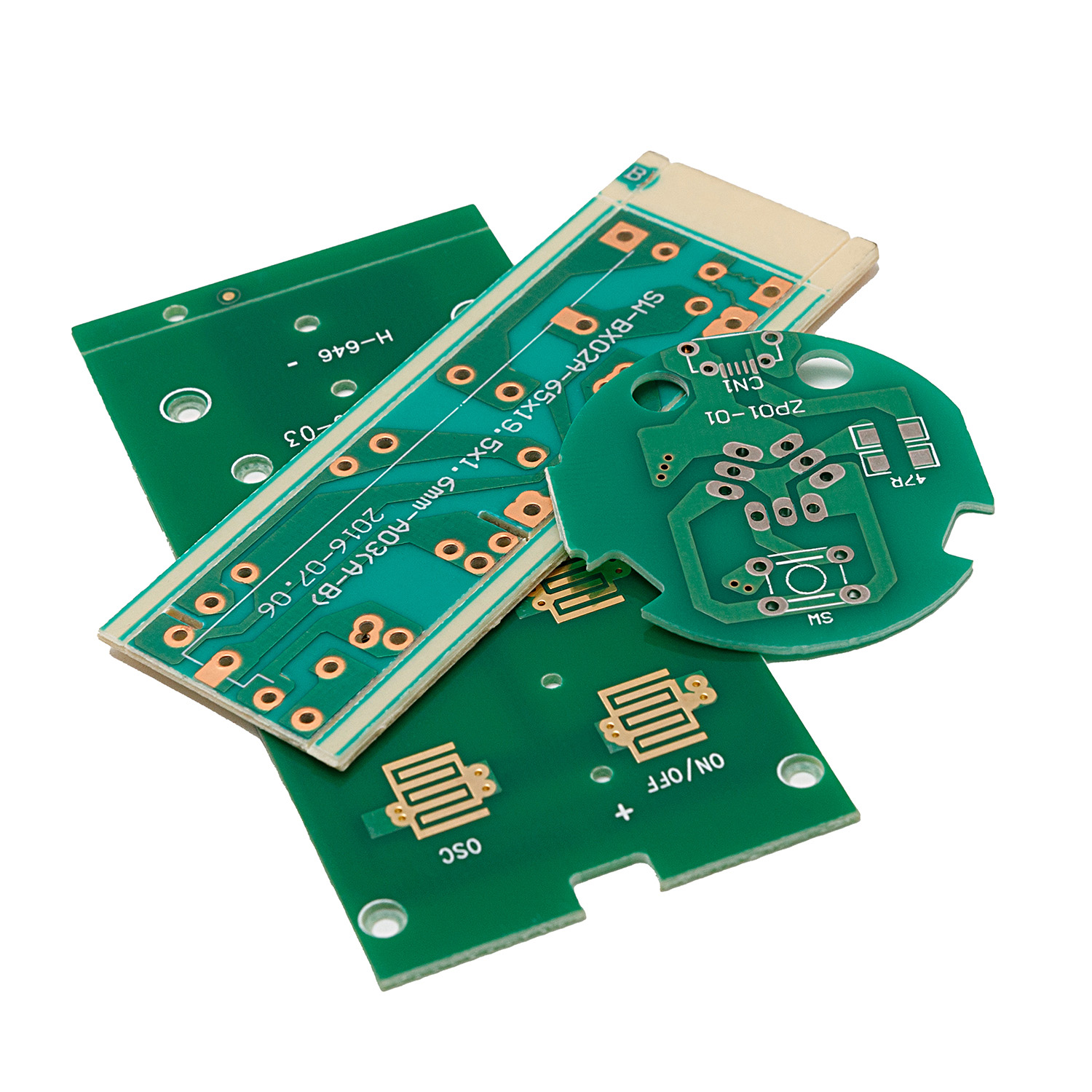

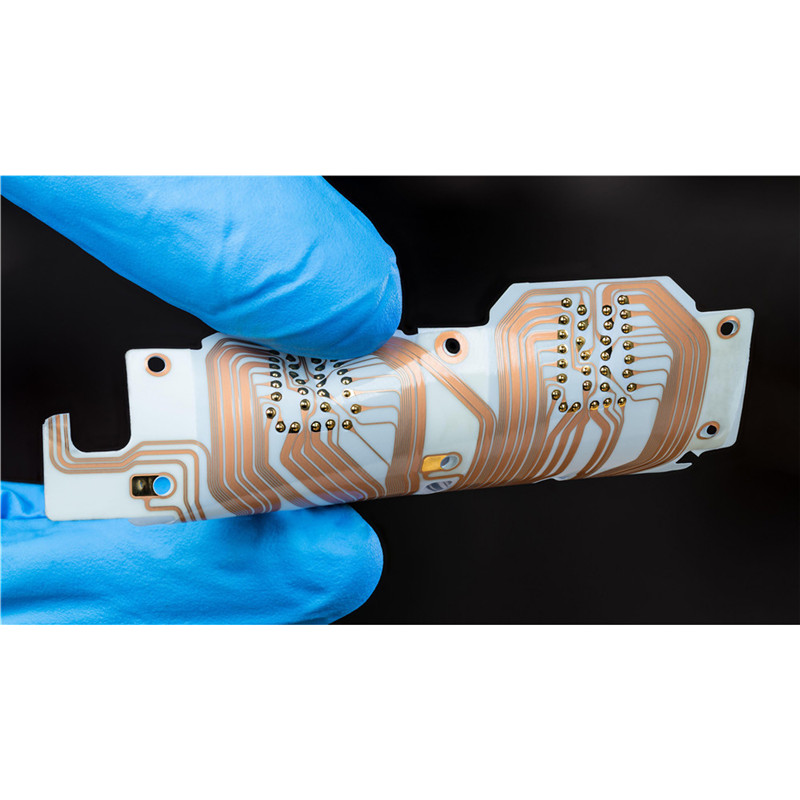

Flexible Printed Circuit Boards

Flexible PCB Applications

Rigid plates have added some limitations in product design as they cannot be installed in limited spaces. Circuit boards need to have vibration resistance in products that are often subjected to mechanical impact.

Flexible PCBs are more suitable for this situation as they can be bent and wrapped if needed. They can survive in harsh temperatures ranging from -200 to 400 degrees Celsius. Compared to traditional circuit boards, these functions make flexible circuit boards more reliable and durable.

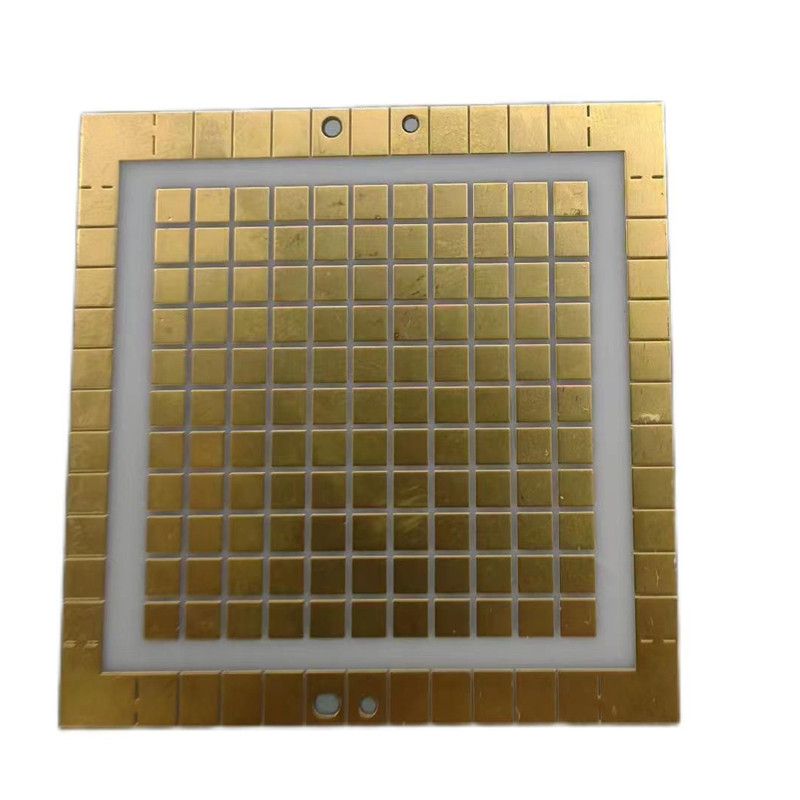

Advantages of Ceramic PCB

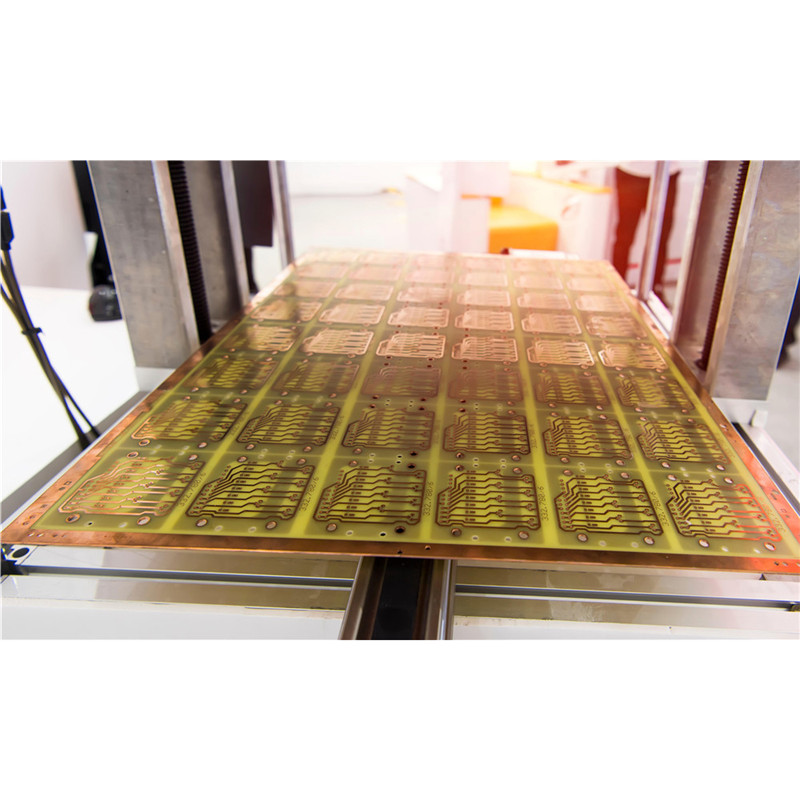

|

Feature |

AREX´s technical specification |

|

Number of layers |

1 – 6L |

|

Technology highlights |

Mainly polyimide materials, flex PCB’s are necessary when motion of the PCB is needed, when 3-D interconnections are necessary (i.e. replacing cables and connectors) or when these are both combined due to limited available space. |

|

Materials |

Polyimide, Polyester |

|

Profile method |

Laser cutting, punching, rout |

|

Copper weights (finished) |

18μm – 70μm |

|

Minimum track and gap |

0.075mm / 0.075mm |

|

PCB thickness |

0.05mm – 0.80mm |

|

Maximum dimensions |

450mm x 610mm |

|

Surface finishes available |

OSP, ENIG, Immersion tin, Electrolytic gold, Gold fingers |

|

Minimum mechanical drill |

0.15mm |

|

Minimum laser drill |

0.10mm standard, 0.075mm advanced |