Medical Equipment

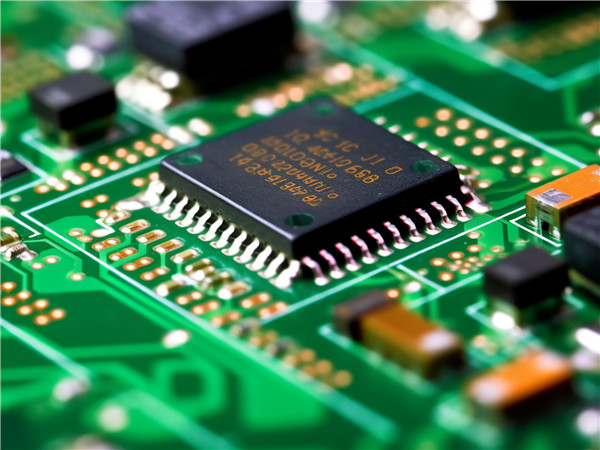

In the modern medical device industry, the quality of PCBA processing technology will determine the product quality of medical equipment. With the rapid development of technology, the design and functional requirements of medical devices have become increasingly complex, and the application of printed circuit boards (PCBs) has become indispensable in this process. This article will delve into the application of PCBs in the field of medical devices and the challenges faced by such applications.

The Application of PCB in the Medical Device Industry

PCB has a wide and diverse range of applications in the medical device industry, covering various aspects from portable medical devices to complex medical image processing systems. The following are several important application areas of PCB in the medical device industry:

1. Portable medical devices: Nowadays, more and more medical devices require portability and small size for use in medical sites or mobile clinics. PCB assembly technology makes it possible to integrate various electronic components in limited space, thereby achieving high-performance and precise measurement of portable medical devices.

2. Medical image processing: Medical image processing systems, such as X-ray, nuclear magnetic resonance, and ultrasound imaging devices, require highly complex circuits to process and present image data. The high-density wiring and precise connection capabilities of PCBs enable these systems to quickly and accurately process image data, providing doctors with accurate diagnostic results.

3. Vital sign monitoring: Vital sign monitoring equipment in medical devices requires high-precision sensors and data processing circuits. PCB assembly technology can achieve the high sensitivity, high stability, and low power requirements of these devices.

4. Surgical equipment: Accurate control and data transmission are crucial in surgical procedures. The application of PCB enables surgical equipment to monitor and transmit data in real-time, assisting doctors in making more accurate surgical decisions.

The challenges faced by PCBs in the medical device industry

Although PCBs have broad application prospects in the medical device industry, they also face some challenges:

1. Reliability and stability: Medical devices require a high degree of reliability and stability to ensure the safety of patients. The manufacturing and assembly quality of PCBs must meet strict standards to ensure that the equipment will not malfunction during long-term use.

2. Medical regulations: The medical device industry is strictly regulated by regulations and standards. The application of PCBs in medical devices must comply with relevant medical regulations, which poses additional challenges for manufacturers.

3. Design complexity: The design of medical devices has become increasingly complex, requiring highly integrated electronic systems. The design of a PCB must meet complex wiring, connection, and heat dissipation requirements, which require advanced design and manufacturing techniques.

4. Durability: Medical devices typically require frequent disinfection and cleaning, and PCBs and other electronic components must have sufficient durability to withstand these environmental impacts.

In summary, the application of PCBs in the medical device industry is constantly increasing, providing key support for medical diagnosis, treatment, and monitoring. However, addressing challenges such as reliability, regulation, design complexity, and durability is an important factor in ensuring the successful application of PCBs in medical devices. With the advancement of technology, PCB technology will continue to provide strong support for the innovative development of the medical device industry.